Cleaning for Biopharmaceutical Production

- Minimal space required

- High throughput

- Maximize efficiency, reliability, and traceability

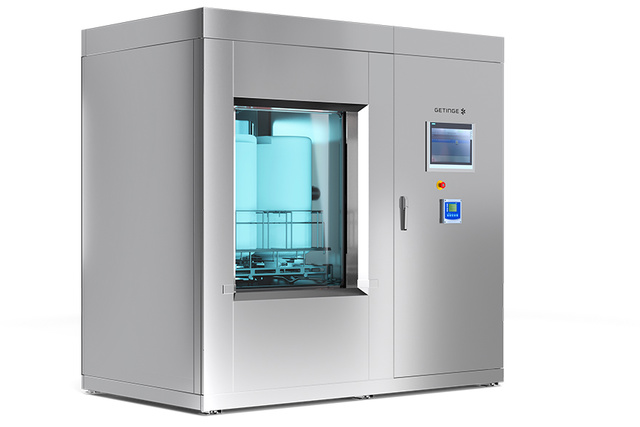

The GEW Series washer/dryers are suitable for many common applications within BioPharma production, and are equipped with appropriate features and options for demanding processes within production and QA/QC laboratory environments.

Future-proof cleanroom performances with SIMATIC WINCC Unified

Open and flexible visualization system for both cleaning and sterilization in the biopharma industry. Excellent operator control and monitoring with SIMATIC HMI, integrated in both Getinge cGMP washers and sterilizers. The new generation washers and sterilizers come with the latest open interface, SIMATIC WinCC Unified, to meet the challenges of digitalization in the pharmaceutical industry. The SIMATIC HMI Unified Panels allow for collaboration between Getinge cGMP washers and sterilizers to reduce engineering effort and to seamlessly integrate usability.

Single pass final rinse

To meet specific process requirements, Getinge offers a Single Pass Final Rinse (SPFR) system which can be programmed as a part of the total validated cycle. During SPFR, components are not exposed to recirculated water. The SPFR cycle can be user-programmed and repeated in accordance with process requirements. Rinse water conductivity is monitored by the control system. If the conductivity goes out of range, a fault code is activated.

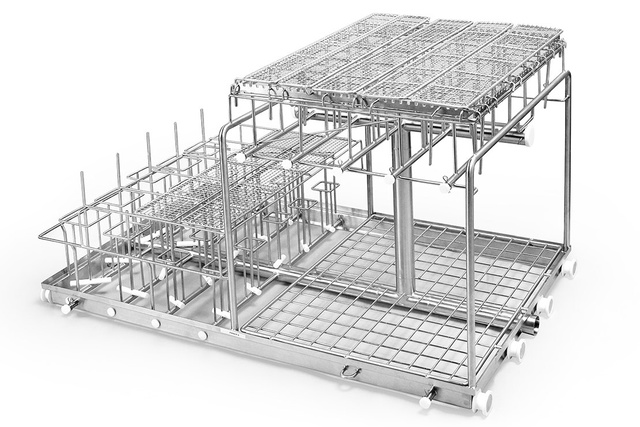

Loading rack identification & AutoStart

The loading rack identification & AutoStart function will identify the wash loading rack and guarantee that the correct wash program is preset and started, according to the validated process and SOP.

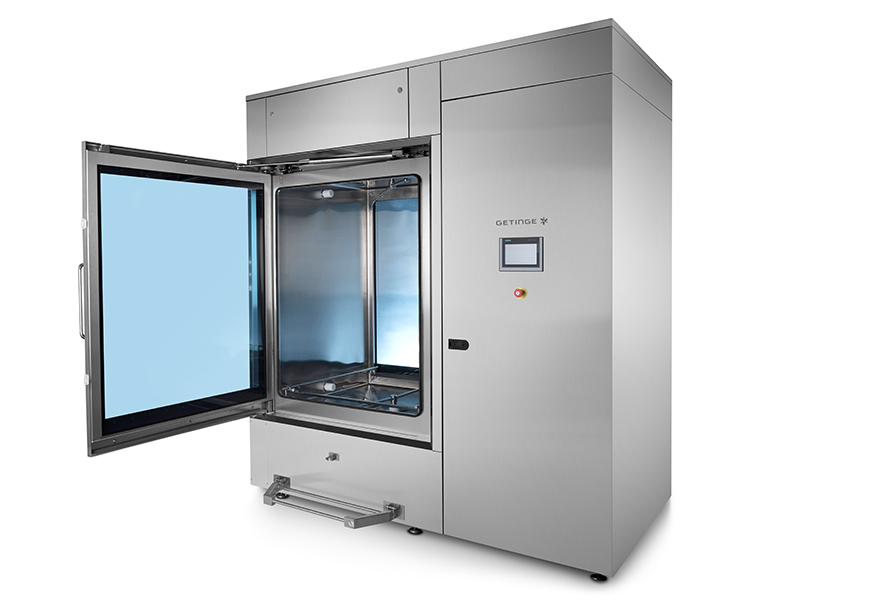

Door configurations

Each model is available in single door or double door configuration. Doors are equipped with interlocks to prevent opening during washer operation and simultaneous opening of the dual door units.

Robust and sanitary construction

Sloped design and smooth crevice-free construction of chamber, piping, and racks eliminate water retention and sites for biofilm or corrosion.

316L stainless steel is used throughout, with EPDM, PTFE, or other FDA (21 CFR part 177) and USP class VI approved gaskets. Orbital welding is used wherever possible and extensive documentation is provided.

Solving the challenge of API exposure

The Air Exhaust Unit for cGMP GEW Washer/Dryer is a standalone solution with a highly effective HEPA filtration system that captures potent and highly potent APIs. The system protects you, your employees, and your environment from the potential dangers of API exposure.

Inventory systems

Getinge optimize washer/dryer accessories to assure a safe, ergonomic systems, customized for specific items and processing needs to ensure optimal cleaning of glassware and components.

Models

The Getinge GEW Series consists of a range of chamber sizes that offer optimal handling of common loads. Five standard models, with a wide variety of options provides a custom configured washer/dryer to meet specific process needs.

GEW 9109

The GEW 9109 is an ideal washer for multipurpose applications. Its 810 liter chamber allows for washing on two levels with ultra-low water consumption. In addition to low cycle costs and high productivity, the automatic sliding doors allow for good ergonomics.

GEW 101210

The medium sized GEW 101210 are designed primarily for the manufacturing area. The base model of each includes many standard features necessary for GMP compliance. The chambers are equipped with one or two vertical hinged glass doors for single ended use or pass-through operation. The hinged door optimizes space and minimizes footprint.

GEW 131313

The GEW 131313 are just as the GEW 101210 designed for the manufacturing area and comply with GMP requirements. The washer can be configured with single or double door for operations requiring pass-through functionality, where the vertically hinged doors minimizes the footprint needed.

GEW 131820

This unit is intended for BioPharmaceutical manufacturing operations, including cleaning of bulk chemical containers, vessels and machine parts. It is designed for pit mounting in a 320 mm (12.6") deep pit, allowing direct floor loading of large, heavy or bulky items. Where pit mounting is not possible, the machine may be floor mounted with a loading height of just 320 mm (12.6").

Marketing Sales - Brochures

-

Cleaning for Biopharmaceutical Production

White Papers

-

Learn how Getinge helps pharmaceutical manufacturers simplify compliance and validation during washing/drying.

-

Discover how Getinge's Life Science equipment supports secure operation, in relation to the key elements of industrial cybersecurity.

-

Getinge's statement of compliance of its GMP pharmaceutical washers and sterilizers controlled by WinCC Unified software to 21 CFR Part 11 and Annex 11 standards.