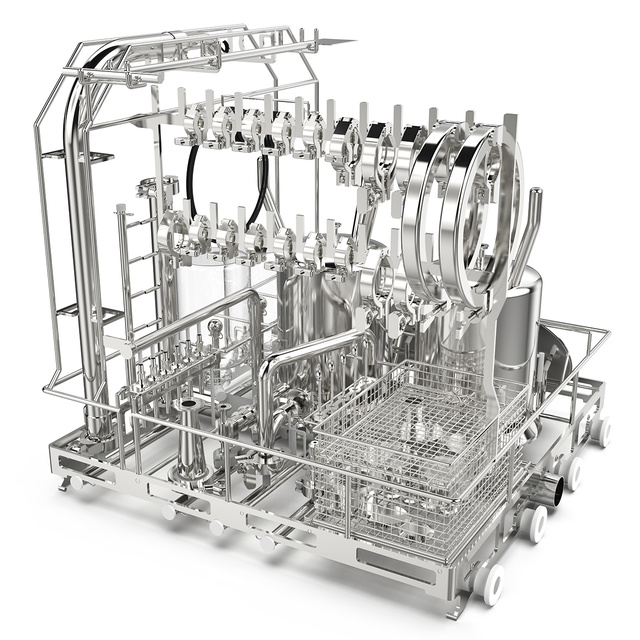

Modular Rack Solutions for GMP GEW Washers

- Ensure optimal cleaning of glassware and production components

- Standard rack solutions including configurated modules

- Customized design

Smooth, uninterrupted production requires that the right components and equipment are available and ready for use. You need the correct, ergonomically friendly loading equipment to ensure efficient use of chamber space and reliable cleaning efficacy. Getinge supports you with standard and customizable rack options for GEW GMP washer-dryers to accommodate a wide variety of loads.

Related products

Sanitary design for biopharmaceutical production

Getinge GMP wash racks are designed to meet the sanitary demands of biopharmaceutical producers. The water recirculation system in the racks is sloped to eliminate water retention that can result in contamination.

Sanitary spray systems combined with injection outlets ensure complete and uniform coverage of both internal and external surfaces of processed items.

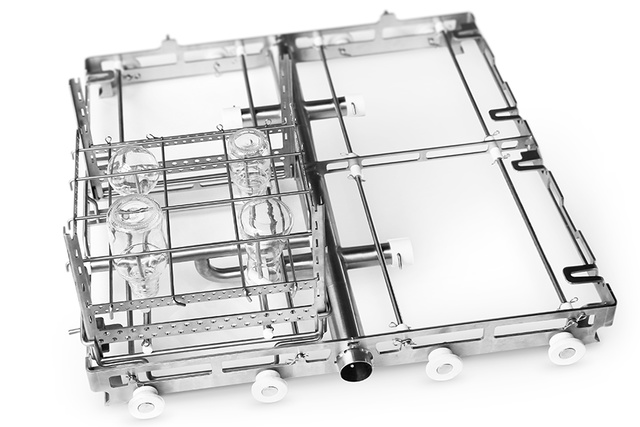

Modular design offers loading flexibility

There’s no need to replace an entire rack when processes or parts change. Modular GMP wash racks give your biopharma production facility the cost-effective flexibility to process a wider variety of items.

Modular GMP wash racks are built on a standard base frame. One or more modules can be inserted into the frame to create custom configurations that meet your process requirements. Modules are easier to handle than complete racks, reducing operator strain.

Customized design for precision cleaning

In a GMP-validated cleaning and drying process, fluids must reach all surfaces of the processed item.

Experienced Getinge designers use 3D CAD modeling and 3D printing to design and development. These models test a broad array of scenarios to ensure that every corner and cavity of your items are thoroughly cleaned.