Speed up your process by cultivating strains in parallel

- Low and uniform evaporation rates

- Sterile barrier for individual wells prevents cross contamination

- Oxygen transfer rates similar to shake flasks in standard orbital shakers

- Conversion of 24 and 96 microtiter plates (both deep and low-well plates) into individual micro-bioreactors

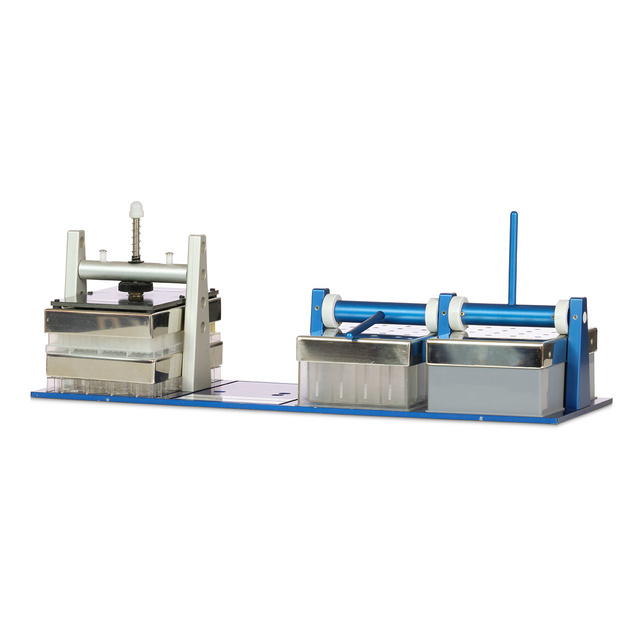

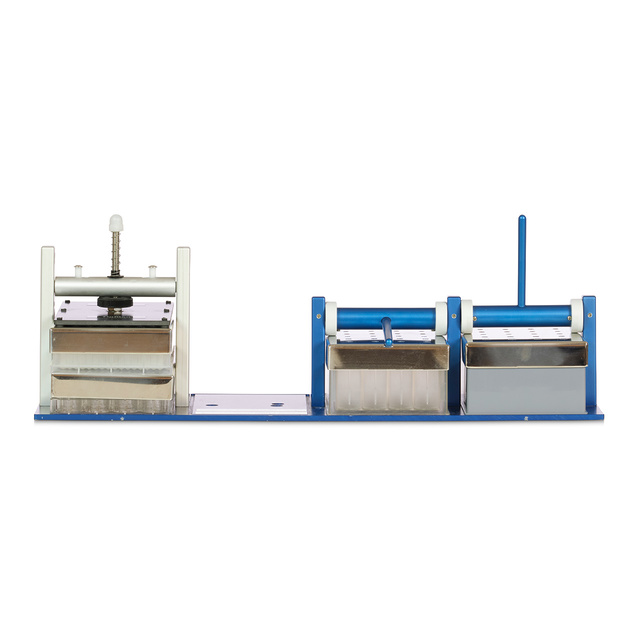

- Simultaneous and reproducible sampling of 96 frozen glycerol stocks using our Cryo-Replicator

All handling with the Micro-Flask is performed in parallel with sets of 24 or 96 strains. It provides a more efficient use of your current orbital shaker, with time savings up to a factor 10 possible. It allows for the same quality of growth as in Erlenmeyer flasks in terms of oxygen transfer rates and reproducibility.

Consumables & Accessories

The Applikon Micro-Flask allows for:

- various square deep-well and round low-well microtiter plates

- a Sandwich-cover (silicone seal, ePTFE + microfibre layer and stainless steel cover)

- a clamp

- a Cryo replicator and press

Related products

Individual micro-reactors

The Micro-Flask turns 6, 24 and 96-well microtiter plates into individual micro-reactors enabling simultaneous and reproducible cultivations.

Transfer of oxygen

The oxygen transfer in the Micro-Flask is similar to fermenters enabling accurate cultivations.

Specifications

| Type of microtiter plate |

Well volume | Culture volume | Orbital shaking frequency | Shaking amplitude | O2-transfer rate (30˚C, air, 1 bar) |

Headspace refreshment rate | Evaporation rate per well (at 30˚C) |

Mixing pattern at 300 rpm |

|

|

|

ampl. 25 mm |

ampl. 50 mm |

|||||||

| 24-square deep-well polypropylene, 17x17 mm, depth 40 mm |

11000 µL | 2500 µL | 300 rpm | 50 mm | 51 mmol O2/l/h | 2.5 mL / min (1 VVM) |

50% humidity: 75% humidity: |

2500 µL | 2500 µL |

| 2500 µL | 300 rpm | 25 mm | 39 mmol O2/l/h | ||||||

| 2500 µL | 220 rpm | 50 mm | 35 mmol O2/l/h | ||||||

| 4000 µL | 300 rpm | 50 mm | 24 mmol O2/l/h | 2.5 mL / min (0.6 VVM) |

|||||

| 4000 µL | 220 rpm | 25 mm | 24 mmol O2/l/h | ||||||

| 24-round low-well polystyrene, ⌀16 mm, depth 18 mm |

3000 µL | 750 µL | 300 rpm | 50 mm | 40 mmol O2/l/h | 1.1 mL / min (1.4 VVM) |

50% humidity: 75% humidity: |

1000 µL | 1000 µL |

| 750 µL | 300 rpm | 25 mm | 25 mmol O2/l/h | ||||||

| 1000 µL | 300 rpm | 50 mm | 30 mmol O2/l/h | 1.1 mL / min (1.1 VVM) |

|||||

| 1000 µL | 300 rpm | 25 mm | 19 mmol O2/l/h | ||||||

| 96-square deep-well polypropylene, 8x8 mm, depth 40 mm |

2400 µL | 500 µL | 300 rpm | 50 mm | 38 mmol O2/l/h | 1 mL / min (2 VVM) |

50% humidity: 75% humidity: |

750 µL | 750 µL |

| 500 µL | 300 rpm | 25 mm | 12 mmol O2/l/h | ||||||

| 750 µL | 300 rpm | 50 mm | 24 mmol O2/l/h | 1 mL / min (1.3 VVM) |

|||||

| 750 µL | 300 rpm | 25 mm | 7 mmol O2/l/h | ||||||

| 1000 µL | 300 rpm | 50 mm | 18 mmol O2/l/h | 1 mL / min (1 VVM) |

|||||

| 1000 µL | 300 rpm | 25 mm | 3 mmol O2/l/h | ||||||

| 96-round low-well polystyrene, ⌀6.5 mm, depth 11 mm |

380 µL | 100 µL | 300 rpm | 50 mm | 39 mmol O2/l/h | 250 µL / min (2.5 VVM) |

50% humidity: 75% humidity: |

150 µL | 150 µL |

| 100 µL | 300 rpm | 25 mm | 20 mmol O2/l/h | ||||||

| 150 µL | 300 rpm | 50 mm | 32 mmol O2/l/h | 250 µL / min (1.7 VVM) |

|||||

| 150 µL | 300 rpm | 25 mm | 16 mmol O2/l/h | ||||||

| 200 µL | 220 rpm | 50 mm | 12 mmol O2/l/h | 250 µL / min (1.3 VVM) |

|||||

| 200 µL | 300 rpm | 25 mm | 12 mmol O2/l/h | ||||||

The Applikon Micro-Flask is ideal for the following applications:

- Growth medium optimization studies

- Comparative studies e.g. clinical isolates

- Screening and distribution of clone libraries in E. coli or yeasts

- High-throughput screening for high-activity or high-productivity mutants

- High-throughput screening for new enzyme activities or formation of secondary metabolites (heterogeneous culture collections)