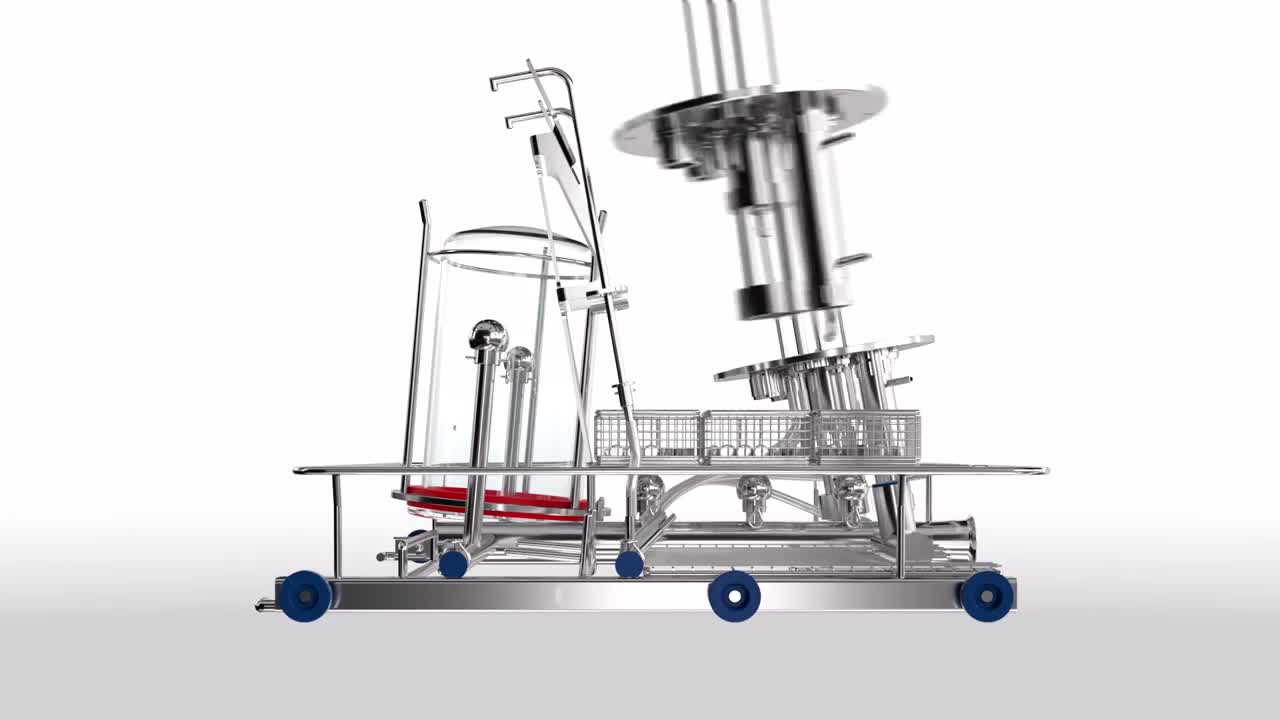

Easily configure your glass autoclavable bioreactor to changing process demands

- Simple set-up and easy handling

- Wide range of volumes to fit many applications

- Easy cleanability by electropolished finish of the product

- Interchangeable modules to tailor the systems to research demands

The Applikon Bio is easy to upgrade if a change in research activities occurs, whether it involves cell culture applications or microbial culture applications. Because of the modularity and flexibility, you can always adapt the system to

changing process demands. This results in low initial investment and low running costs.

The stirred tank reactor (STR) is the most widely used bioreactor type. Getinge Applikon multi-use bioreactors and fermenters are available in 2 / 3 / 5 / 7 / 15 / 20 liter total volume.

Advances in bioreactor washing

The programmable Getinge Ultima Lancer labware washer with specialty washer rack for the multi-use 1-3 L bioreactors assures thorough cleaning, better reproducibility and reduced labor.

Watch the video to view how the Getinge Applikon bioreactors and Getinge Lancer washers bring you a holistic solution for lab applications.

This Applikon bioreactor straight in your lab

Are you interested in the multi-use Applikon bioreactor, and would you like to get a virtual sample right now? Try this bioreactor in Augmented Reality*.

Scan the QR code on your desktop with your mobile device or click on the link directly on the mobile device and discover how the Applikon Bio would be on your bench.

*View this page on an Augmented Reality (AR) compatible device. Augmented Reality (AR) adds digital elements to the camera of your smartphone, creating the illusion that holographic content is a part of a physical world around you.

Applikon Bio 3 L

Does a multi-use bioreactor better match your application?

Experience the multi-use Bio 3 L in your lab.

Borosilicate glass

The glass dished bottom vessels are made of borosilicate glass to guarantee:

- resistance to thermal shock

- excellent corrosion resistance

- smooth, non porous surface for easy cleaning

- optimal transparency for visual inspection of the culture

High quality parts

The system is built according to the specific demands of a process using an extensive array of high quality components. All metal parts of the bioreactor are constructed of stainless steel 316L. There are no welded parts in the bioreactor top plate, which simplifies the sterilization of the bioreactor after each run.

Up to 0.5 barg

The glass bioreactor vessels can be used up to 0.5 barg (7.5 psig) of overpressure.

Specifications

| Total volume (L) |

Working volume (L) |

Minimum working volume (L) |

Aspect ratio total volume (L) |

Aspect ratio working volume (L) |

|

| 2 liter single wall | 2.2 | 1.7 | 0.5 | 2.2 | 1.9 |

| 2 liter jacketed | 2.2 | 1.7 | 0.5 | 2.2 | 1.9 |

| 3 liter single wall | 3.1 | 2.7 | 0.5 | 1.9 | 1.5 |

| 3 liter jacketed | 3.1 | 2.7 | 0.5 | 1.9 | 1.5 |

| 5 liter single wall | 4.8 | 3.4 | 0.9 | 1.6 | 1.1 |

| 5 liter jacketed | 4.8 | 3.4 | 0.9 | 1.6 | 1.1 |

| 7 liter single wall | 6.8 | 5.4 | 1.5 | 2.2 | 1.8 |

| 7 liter jacketed | 6.8 | 5.4 | 1.5 | 2.2 | 1.8 |

| 15 liter single wall | 16.5 | 12 | 3.0 | 1.7 | 1.5 |

| 15 liter jacketed | 18.2 | 12 | 3.0 | 1.5 | 1.2 |

| 20 liter single wall | 23.4 | 16 | 3.0 | 2.4 | 2.0 |

| Internal Diameter (mm) | Internal Height (mm) | Autoclave dimensions (WxH mm) | |

| 2 liter single wall | 105 | 240 | ø190 x 436 |

| 2 liter jacketed | 105 | 240 | ø219 x 486 |

| 3 liter single wall | 130 | 240 | ø190 x 436 |

| 3 liter jacketed | 130 | 240 | ø235 x 436 |

| 5 liter single wall | 160 | 250 | ø260 x 436 |

| 5 liter jacketed | 160 | 250 | ø260 x 480 |

| 7 liter single wall | 160 | 350 | ø260 x 600 |

| 7 liter jacketed | 160 | 350 | ø264 x 645 |

| 15 liter single wall | 222 | 440 | ø381 x 710 |

| 15 liter jacketed | 240 | 440 | ø391 x 740 |

| 20 liter single wall | 222 | 620 | ø381 x 900 |

| Drive system | Direct drive, lipsealed or magnetically coupled |

| Stirrer speed (rpm) | Standard range is 50 - 1250 2 and 3 liter systems can be supplied with 2000 rpm motor |

| Impellers | Rushton and marine with outside diameters 45 mm, 60 mm 75 mm or 85 mm |

| Gas sparger | Porous sparger or L-type sparger |

| Gas overlay | Yes |

| Exhaust gas | Water cooled exhaust gas condenser |

| Sampling | Fixed height or height adjustable sample pipe with optional sampling system Sample pipe internal diameters choices are: 1.7 mm, 4 mm, 6 mm or 10 mm |

| Draining | Drain pipe |

| Additions | Triple or single inlet ports and optional micro liquid injectors |

| pH | Measurement: 12 mm classic pH sensor |

| Control: via acid pump or CO2 gas (rotameter or MFC) in combination with alkali pump | |

| DO2 | Measurement: 12 mm classic polarographic DO2 sensor or LumiSens for 2-5 L Control: via a combination of N2, Air, O2 (Rotameter or MFC) and agitation |

| Temperature | Measurement: Pt-100 sensor in thermowell in top plate Control: cooling and/or heating jacket via bioreactor wall or via internal heat exchanger |

| Foam | Measurement: Height adjustable conductivity based foam sensor Control: anti-foam addition pump |

| Level | Measurement: Height adjustable conductivity based level sensor Control: pump for liquid addition or removal |

| Optional inlets | Septum, chemostat tube, liquid entry system |

The Applikon Bio is ideal for the following applications:

- Microbial cultures

- Cell cultures

- Batch

- Fed-Batch

- Perfusion

- Continuous cultivation

Visit our Academy – training and education designed to enhance your proficiency

For more information about our onsite events or remote trainings, please contact your local sales & service representative.