Maximizing throughput for washer-disinfectors

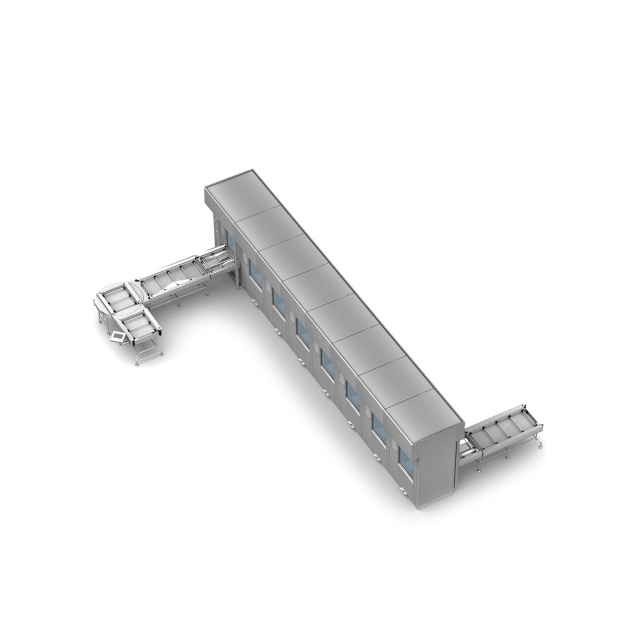

The Getinge Automation System for washer-disinfectors maximizes the efficiency with cleaning, disinfection and transportation of instruments from soiled to the inspection and packing area.

Customized to your needs, using the space you have

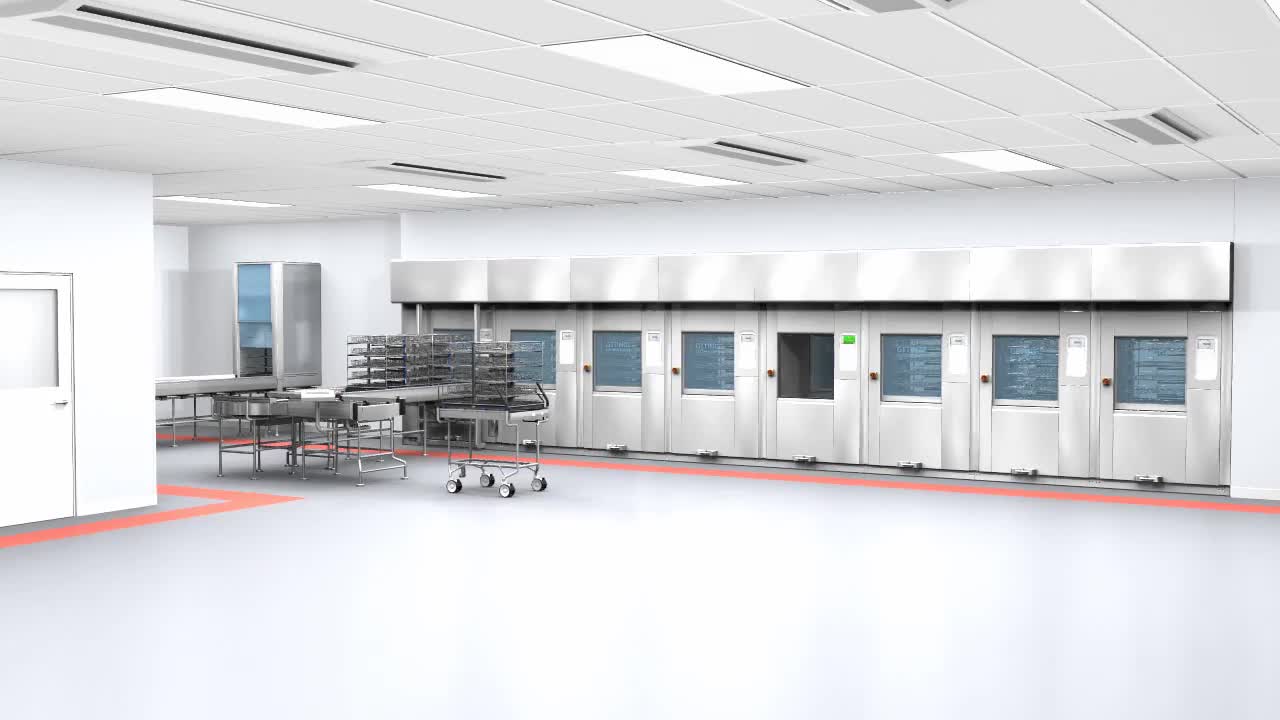

The principle of the Getinge Air Glide System (AGS) is "no waiting". When a unit becomes available, the shuttle automatically picks up the next wash-cart and delivers it to the available washer. No supervision is required and it can all be automatically documented for full traceability. It is especially useful where space is at a premium and limited staffing cannot afford the time it takes to move each wash cart into place, load each unit and select the correct program for the goods being processed.

Getinge Air Glide System (AGS) 2.0 is a fully automatic and highly flexible loading and transport system providing maximum productivity and efficiency for customers with multiple Getinge 88 Turbo or 8668 washer-disinfectors.

It is especially useful where space is at a premium and limited staffing cannot afford the time it takes to move each wash cart into place, load each unit and select the correct program for the goods being processed.

Fully automatic and highly flexible loading and transport system for 3-10 washer-disinfectors

Optimal workflow regardless the size of the facility

User-friendly design minimizing bottle-necks and risk for human errors

Ergonomic and hygienic

Motor-driven rollers provide easy loading and unloading of the wash carts

Free floor area in front of washers for easy cleaning and access

Pull-out service frame for easier access of components from both sides of the washer-disinfectors

Adapted for 8666 (no AGS), 8668 and 88-series washer-disinfectors

Marketing Sales - Brochures

-

Product brochure

-

Accessory brochure