Turnkey automation solution for process optimization

- Reduced time-to-market and development costs

- Improved user experience with advanced automation tools

- Minimized scale-up risks with easy technology and data transfer

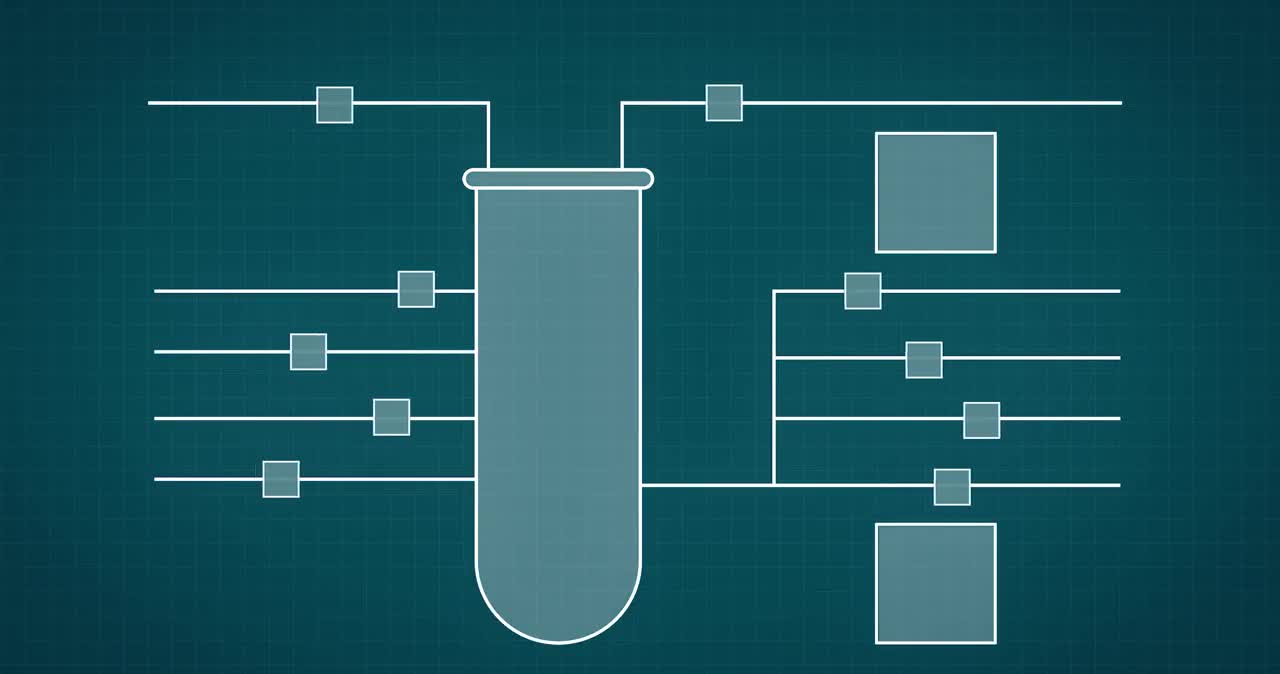

Applikon V-Control is a joint effort as a result of being a premier partner of Emerson’s OEM program for life sciences. It combines the state-of-the-art Applikon bioreactor systems with Emerson’s awarded DeltaV automation solution.

V-Control is the scalable DeltaV™ solution for bioreactors from discovery to production. In labs, it harnesses the power of DeltaV™ in an off-the-shelf configurable system at a reduced price point. For pilot and production scale stainless steel or single-use systems, it harnesses the power of the DeltaV PK Controller in a configurable control system based on user requirements.

One common platform

V-Control combines the best of DeltaV™ automation with Applikon bioprocessing know-how into one platform for process control and data management from discovery to production. The open architecture in V-Control enables users to optimize the DeltaV libraries for their processes and allows user to merge the application with existing DeltaV library. Seamless technology transfer and scalable data transfer result in optimal bioprocesses with shorter development lead times and lower development costs.

One platform to enable an improved quality of life

Scaling up between different process development phases from Discovery to Production can be a challenging task for drug developers; data and technology transfer within a multi-platform environment can be very time-consuming, while translation from one platform to another also increases the risks of errors.

Watch the video to view how V-Control can support in smooth data and technology transfer.

V-Control for R&D

The V-Control R&D version is optimized for bioprocessing and will combine DeltaV Discovery with scalable laboratory Applikon bioreactors ranging from 250 mL up to 20 L.

The DeltaV Discovery system exists of a DeltaV ProfessionalPlus PC which will combine process control, data acquisition, visualization, and recipes in one single PC at a reduced bench space. The DeltaV Discovery system can be expanded up to 32 bioreactor units per network and may be expanded with additional DeltaV application and operator stations as needed. The DeltaV Discovery system will communicate to the Applikon control systems, such as my-Control and ez2-Control through OPC, and DeltaV will be the sole interface for operators for process control, data acquisition, visualization, and recipes. This will reduce operator training programs and will simplify workflows.

The Applikon single-use and multi-use bioreactor systems can be configured to meet customer requirements, such as multiple gas flows, integration with 3rd party sensors, and additional pumps. Furthermore, V-Control can be expanded with several add-on packs such as V-Control Batch for R&D and DeltaV Configuration Audit Trail & Version Management. It can be integrated with external historians like OSIsoft PI.

V-Control for Pilot & Production

V-Control for Pilot & Production is the scalable DeltaV solution for bioreactors in pilot and production applications. V-Control for Pilot & Production is using Emerson’s DeltaV PK Controller and is used for Applikon stainless steel and single-use bioreactors for pilot and production. When it is preferred to use the DeltaV PK Controller in combination with Applikon lab bioreactor systems, V-Control for Pilot & Production can also be used in combination with the Applikon my-Control, in-Control and ez2-Control.

Using Emerson’s DeltaV PK Controller, Getinge can provide powerful stand-alone or integrated stainless steel and single-use bioreactor systems. Through the open-architecture of V-Control, and by using native DeltaV tools, these systems can be easily integrated into other DeltaV systems. This enables a seamless integration in the balance-of-plant and with downstream facilities.

V-Control for Pilot & Production utilizes the same V-Control DeltaV application as V-Control for R&D, which guarantees seamless technology transfer from R&D to Pilot & Production, resulting in a shorter time-to-market and lower development costs.

Off-the-shelf V-Control packages for labs

V-Control for R&D can be fully configured to meet customer needs or can be purchased in pre-configured bundles. The Applikon V-Control for R&D bundle includes:

- Applikon V-Control base package with DeltaV Discovery including, hardware, software, licenses

- Applikon V-Control Batch for R&D add-on with DeltaV Batch

- Applikon V-Control support including Emerson’s Guardian™ support

- 4x 3 L Applikon AppliFlex ST single-use or Applikon Bio multi-use bioreactor

- 4x Applikon my-Control hardware, including:

• 2 variable speed pumps

• 3 mass flow controllers for air, O2 and CO2

• 2 gas lines for sparger and overlay

• pH, DO and temperature sensors

• Heating blanket

• Stirrer motor - All required accessories and start-up kit

- Installation and training

Open-architecture software

The open DeltaV architecture in Applikon V-Control enables easy transfer of DeltaV modules and recipes developed at benchscale into larger scale. DeltaV modules and recipes from other laboratory or production sites that are already using DeltaV can be shared. This enables seamless technology transfer between different sites and results in shortened time-to-market and lower drug development costs. The open architecture also allows users to modify the existing Applikon V-Control library to optimize it for their specifc process and it is also possible to add and modify phases for DeltaV Batch.

User-friendly user interface

The Getinge DeltaV™ application is the application within the V-Control solution that is built by software engineers from both Getinge and Emerson. The interface is built using the default DeltaV™ PCSD library from Emerson to make it easy to use and to connect to existing systems. The end-user experience is enhanced and simplified with Emerson’s Human Centered Design based interface, attracting your attention whenever and wherever needed.

Advanced automation tools

To ensure the best user experience Applikon V-Control includes advanced automation tools:

- sensor and actuator calibration

- total gas flow

- 3-point cascade

- DeltaV™ Batch to support automated recipes

- multi bioreactor overview

Applikon V-Control Batch for R&D

V-Control for R&D can be expanded with DeltaV Batch. DeltaV Batch adds the popular batch functionality to the DeltaV suite and is widely used and recognized in pharmaceutical DeltaV applications. Operators use DeltaV Batch to design and execute batch processes in DeltaV.

V-Control Batch for R&D is based on this powerful DeltaV Batch utility, which is widely used in life sciences industries. V-Control Batch for R&D includes pre-defined phases for common bioprocessing steps. The phases can be easily used by operators as building blocks to create recipes. These recipes can be used to further automate bioprocesses and get more control over the processes, even for operators who are new to DeltaV. Through the open architecture in V-Control users are also able to design their own phases or to transfer and utilize phases that have already been developed by users in other DeltaV applications. Certain DeltaV skills are required for this, therefore trainings are globally available through local Emerson partners. Getinge also offers support to help users without these engineering skills to build and expand recipes based on specific process demands.

The Applikon V-Control is ideal for the following applications:

- Microbial and cell culture

- Batch

- Fed-Batch

- Perfusion

- Continuous cultivation

Marketing Sales - Brochures

-

The scalable DeltaV™ software solution for bioprocesses